Hello TFB readers. We got a chance to test and evaluate the new Oracle Arms OA 2311 pistol. This pistol has gathered quite a bit of excitement within the shooting community. It is sort of a hybrid between a 2011 and a P320. As Oracle Arms says “Duty gun reliability with race gun DNA”.

More 2311 @ TFB:

A 2011 Crossed With A P320?

As Obi-Wan said, “From a certain point of view”. The Oracle Arms 2311 takes certain features and characteristics from a 2011 and the P320. For those who have not had the pleasure and frustration of owning a 2011, they are great guns but they can be finicky. They usually require some level of gunsmithing and fine-tuning to run really well. Even the magazines need tuning especially when it comes to the race guns built from 2011s. One aspect of reliability is having a magazine that feeds consistently. It also helps if they are affordable. Well, Oracle Arms solved this problem by using a tried and true magazine that already exists in large quantities and may be magazines you already have. The OA 2311 is fed from P320 magazines.

Even the 30-rd P320 magazines feed the 2311.

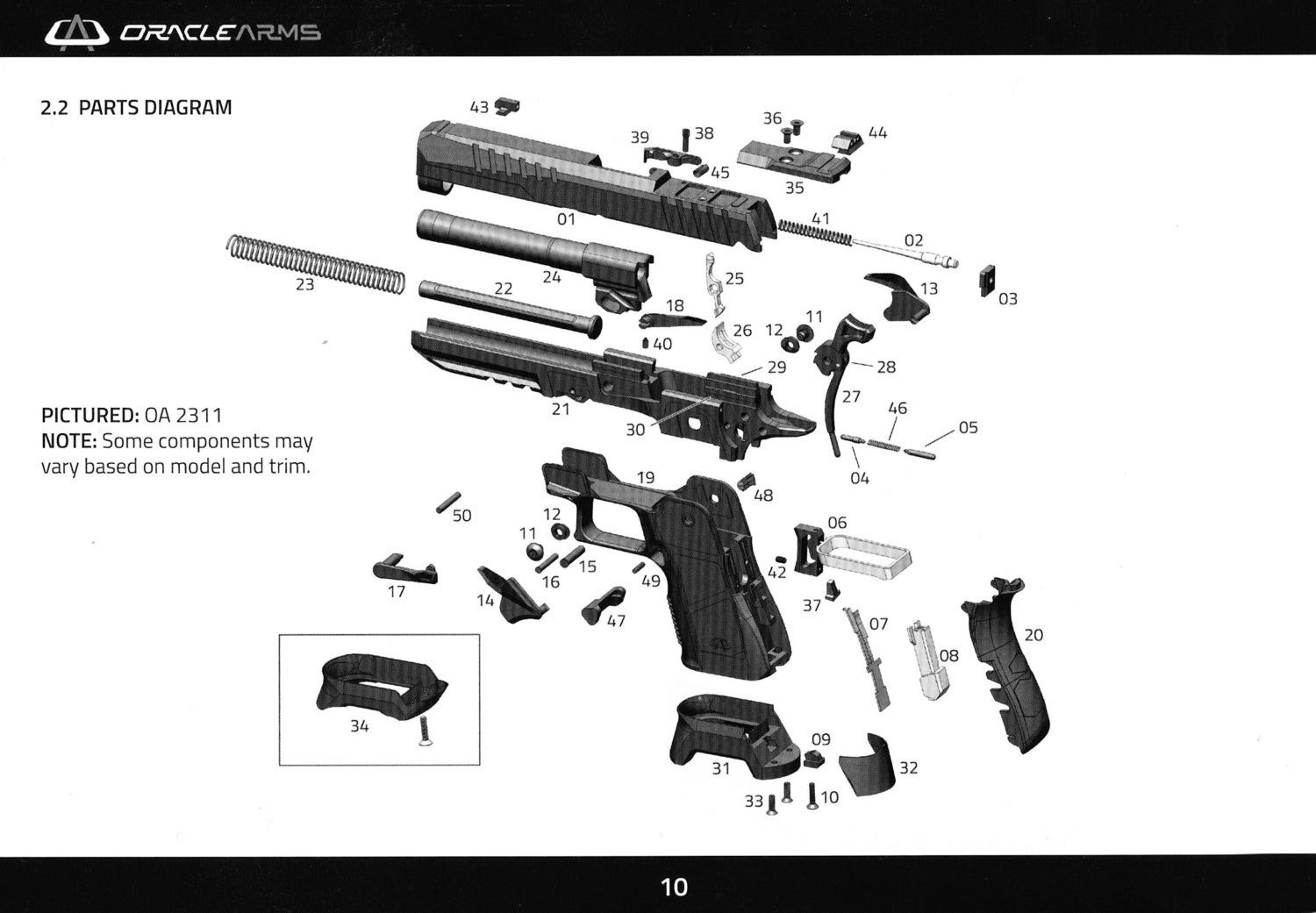

Here is a scan of the parts diagram from the OA 2311 manual. You can see the 2311 has some 2011 similarities like the main spring housing, single action trigger/bow, frame, safeties and of course it is hammer fired.

If you look at the image above you can see the frame and the grip/trigger guard are separate pieces. The frame is milled aluminum and the grip is molded polymer. The grip uses a P320 mag catch and that is where most of the similarities with the P320 end. Besides the magazine and mag catch, everything else is 1911/2011 inspired, sort of.

Unlike a 1911/2011, the barrel, recoil spring and guide rod are more like a CZ75. The recoil spring is not held captive on the guide rod but there is no barrel bushing like a traditional 1911/2011. The spring and guide rod are held in with the slide when you remove the slide from the frame.

You can see right away the OA 2311 barrel has a linkless design similar to a CZ75.

However, the OA 2311 barrel is quite different. Since the barrel sits higher from the frame, the kidney bean-shaped hole sits lower from the chamber compared to a CZ75 barrel.

You can see Oracle Arms’ debris clearance channels between the barrel hood and linkless kidney bean-shaped hole.

Historically, the Achilles heel of a finely-tuned 1911 platform was the tendency to jam or malfunction if dirt or debris got trapped between the moving components of the action. In order to combat this vulnerability, Oracle Arms has engineered patent-pending grooves into key areas of the action and the frame. The location and orientation of these grooves allows the OA 2311 to self-evacuate dirt and debris, reducing the chance of it getting lodged in the action and causing a malfunction.

If we move our attention to the grip it starts to resemble a 1911/2011 a lot more. I removed the backstrap to expose the main spring and other components.

This is the backstrap from the OA 2311.

Let’s take a step back now and look at the entire OA 2311

For full disclosure, Oracle Arms sent in an OA 2311. That gun had some issues so they sent a replacement 2311 in its place. So some of these photos will be of the first or second 2311. They look the same from the exterior except for the serial numbers of course.

When Oracle Arms sent the first OA 2311 they asked if I wanted to test one with an optic already on it. I declined their generous offer and wanted to experience the 2311 as an actual consumer. “Just send a 2311 like you would any other customer”. So it did not come with any red dot but it does come with three optic mounting plates. The two pictures above were taken at my FFL and were the last time I had the rear iron sight cover plate on the pistol. I immediately removed the plate to install my optic of choice.

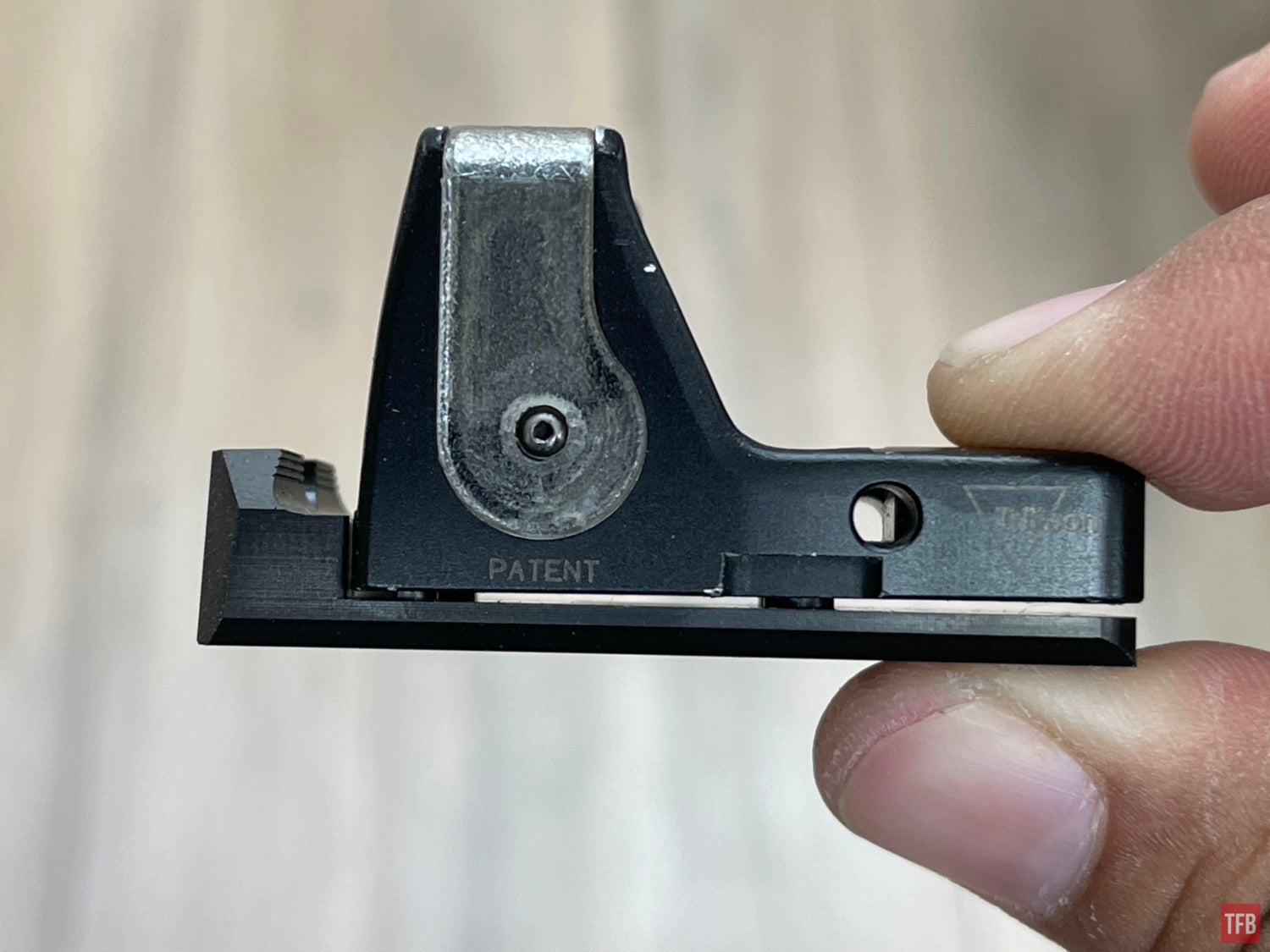

Oracle Arms provides three optics plates. L-R: Leupold DPP, RMSc, & RMR. Interestingly the RMSc and RMR optic plates have raised threaded bosses along with the two recoil bosses near the backup rear iron sight. While the DPP plate already has four recoil bosses. Also, the DPP plate has a raised rear iron sight to coincide with a taller front iron sight to clear silencers. Threaded barrels are not out just yet but coming soon for the 2311.

Here is what the slide looks like underneath. You can see an oval-shaped recoil lug that the bottom of the optic plate interfaces with so the screws are not the only thing holding the optic plate under recoil.

I decided to use my fiber optic/tritium RMR but this is as far as I was able to get the optic onto the plate with my bare hands. I ended up needing to tap it with a soft mallet so it could seat all the way. Talk about tight tolerances!

When I installed the RMR, Oracle Arms only had one set of screws and they were installed in the RMSc optic plate. I incorrectly assumed those are the same for the other plates. So when I used those screws in the RMR optic plate they seemed to work at first but they did not want to tighten all the way. I checked the manual and there was no clarification about the optic plates nor any mention of the screws. I have since brought this up with Oracle Arms and they will be updating the manual.

The screws did not tighten but since I had to use a mallet to get my RMR to seat, I figured it might be ok so I immediately took the OA 2311 to an indoor range to break it in. My contact at Oracle Arms recommended I shoot at least 100 rounds to break it in. Well, within the first couple of shots, my RMR went flying. This was my fault for assuming the screws in the RMSc plate were used for the RMR optic plate. I managed to find one of the RMSc screws.

It is a good thing the optic plate has backup rear irons machined into it. So I was still able to continue aiming at the indoor range to complete the break-in cycle. Interestingly the rear irons have anti-glare grooves machined into them. But I am not sure if it is necessary if you are running a red dot.

Here is the sight picture of the backup iron sight machined into the optic plate, without the optic of course.

When I returned home, I went to my box of parts from the Strike Industries Modular Chassis. It has a variety of screws for almost every style of optic. I found some that looked right for the RMR optic plate and sure enough, they fit and tighten perfectly. See the RMR screw on the left and the RMSc screw on the right. Not at all the same size or thread pitch. This is why those RMSc screws did not work.

I installed my Trijicon RMR but noticed a couple of issues. The first problem was that the screws I was using were too long. When seated and torqued down they protrude past the bottom of the plate and cause the plate to lift away from the slide. See the gap below.

This was an easy fix. I just ground the screws down a bit to make them shorter. The other issue was that the iron sights do not co-witness with my RMR. You can see the rear iron sight is lower than the body of the RMR.

I never noticed it before but the objective lens of the Trijicon RMR is taller than what you actually see. It extends below the top of the rear of the RMR housing. So when looking at the RMR from the front, the rear iron sight looks like it would co-witness. Sadly it does not. The RMR housing sits higher than the iron sights.

What sets the OA 2311 apart from your standard 2011 is that it is ambidextrous. The molded polymer grip has an aggressive texture and molded thumb rests that sort of act like miniature gas pedals.

The thumb safety and slide release are fully ambidextrous.

Since the OA 2311 uses a P320 magazine catch, you need to flip it around 180º if you want to use it for a left-handed shooter.

I have medium-sized hands and I cannot press the mag release with my firing hand thumb. Not unless I break my grip and twist the grip to bring the mag catch closer to my thumb.

Compare that to my SIG M17. I can reach the magazine release with little effort.

If I remove the OA 2311 backstrap, I can reach the magazine release with my thumb. Oracle Arms said they will be coming out with different-size backstraps.

Here is the OA 2311 next to my SIG M17.

I did notice a minor inconvenience with the holster I used for the OA 2311. I used a Black Hawk Omnivore. The safety selector on the left side sits really close to the release of the Omnivore holster. If the grip of the pistol gets bumped and pushes the pistol forward, the safety selector will push up against the holster release and get bumped off safe. This is a minor issue with my holster and the 2311. If I owned this handgun I would get a normal kydex holster made for it.

OA 2311 Magazines

While the OA 2311 takes SIG P320 magazine, it comes with US-made magazines and they are slightly different than the Italian-made P320 magazines.

The Italian-made SIG P320 magazines say “MADE IN ITALY” on the right-hand side and that is also where the witness holes are for how many rounds are in the magazine. The OA 2311 magazine instead says MADE IN USA stamped in the front along with the American flag. Halfway down the magazine tube body is the Oracle Arms logo also stamped into the steel mag body.

The finish on the Oracle Arms mags a a little bit splotchy compared to the SIG magazines. On the left side of the SIG magazine is the caliber and SIG SAUER logo.

I actually like where the Oracle Arms magazines have their witness marks. They are on the back of the magazine. The SIG mags have holes on the right-hand side of the magazine. I rarely look at that side of the magazine as a right-handed shooter. Even the 30-rd SIG magazines have witness holes along the back of the magazine. It is just the 17-rd and 21-rd P320 magazines that have the holes on the right-hand side. I suppose if you are a left-handed shooter, you can grab a SIG mag with your right hand and look at the side to see if it’s full or not as you insert it into the gun. For right-handed shooters that side of the magazine will be pointed away from you either at the floor or down range.

The base plates have their respective company logos on them.

Shooting The OA 2311

As I mentioned earlier, Oracle Arms sent a 2311 but it had issues. I did not know about the issues until I tested the gun. If you recall, I took the pistol to an indoor range to break it in as per Oracle Arms’ instructions. I experienced several malfunctions in those 100+ rounds. I had hoped those issues would be just due to the break-in period so I chose to continue testing the 2311 at a local USPSA match. The pistol had the same issues in all but one stage and while the gun had issues, it was accurate.

See the screenshot below. You had to shoot those targets from either the left or right side of the barricade. You cannot step past the wooden fault line on the ground. Even with the large 6 MOA dot of my dual illumination Trijicon RMR, I managed to get clean double alpha hits on each of the three targets. For those not familiar with USPSA targets, the white upside-down targets are considered “NO SHOOTS”, there are penalties for hitting them. So the only spot to hit the left and right targets is in the brown head box peeking above the white no-shoot. The middle target has a black hard cover on the left and right sides. Only the brown stripe down the center will count. Hits in the black do not count and there is no penalty if you do hit the black sections.

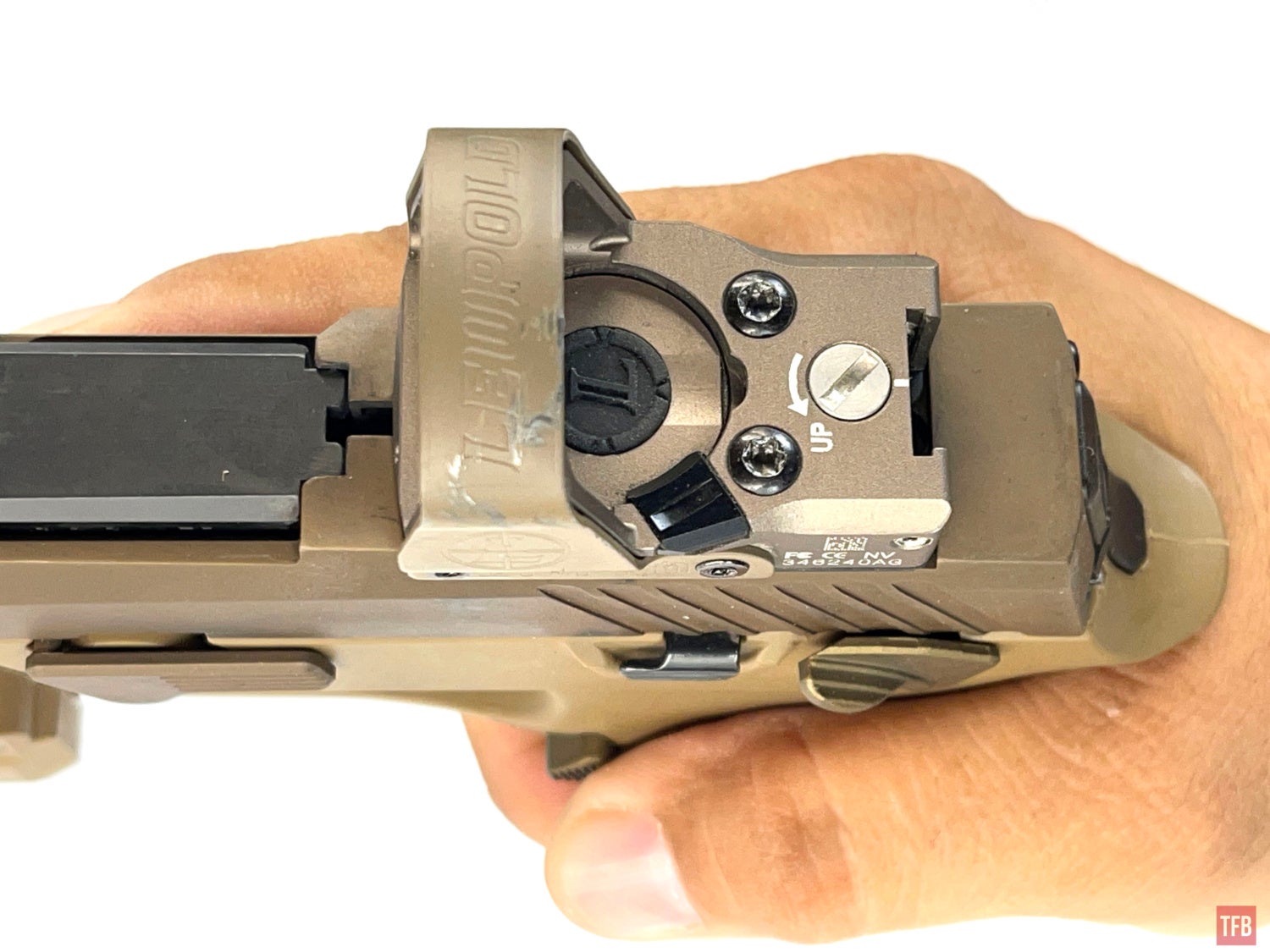

After this match, I reached out to Oracle Arms and told them about the issues the gun was having. They said that is not representative of their quality so they sent a replacement gun right away. One of the engineers at Oracle Arms personally shot 200 rounds through the new gun to make sure it had zero issues. This new OA 2311 came with an RMSx mounted and zeroed to the gun.

The RMSx is low enough that the irons do cowitnesss.

I took the replacement OA 2311 and shot it again in another local USPSA match. I shot it in the Limited Optics Division due to the magwell flare. This time the gun ran flawlessly. I, on the other hand, have not shot USPSA for a long time so my performance was terrible. My poor performance was not the fault of the handgun. When I slow down and actually try, I can hit the things I point the OA 2311 at like steel targets. It is only when I rush and try to go fast, I miss much and my score goes down. I am not getting a good sight picture and just double tapping in some cases but that risk came to bite me in the behind. LOL, but this is just me disappointed in my own sub-par performance.

I wanted to eliminate my poor pistol skills so I let my friend Ki J shoot it in a local night match. He is a B-class shooter in USPSA. He primarily shoots CZs in competition. He liked that it uses P320 mags and the ambidextrous safeties feel like a 2011. The thumb rest is the perfect size and placement for a duty weapon. However, there are some things he did not like. The magwell is an odd shape. It is a little too tall so you really need to make sure the flush-fit 17-rd magazines are really seated. This slows you down. Of course, one can use the 21-round magazines but it wouldn’t be terrible if the magwell was a smidgen shorter for easier mag seating. He found the trigger to be lackluster. The trigger pull was “no better than a Glock and the reset feels slow”. The P320 mag release is a little stiff and the slide serrations are not aggressive enough.

I agree with his assessment the slide serrations do not feel deep enough or sharp enough. So I ended up racking the slide with the optic instead.

Final Thoughts On The Oracle Arms 2311

The Oracle Arms 2311 did everything I asked it to do and never gave me a problem. I like that it can use the same P320 mags I already have. Since I shot in the Limited Optics Division, I was able to use the 21-round factory P320 magazines that I have. The 2311 has an MSRP of $2,199. It is a bit more than your entry level 2011 but you do not need to spend more money getting it to work. The first pistol they sent was a fluke but they were quick to rectify the issue. For more information go to the Oracle Arms website. Thank you Oracle Arms for letting me test drive the 2311.